What is DTP?

DTP is a new thermoelectric cooling and temperature control technology in which the transport properties — Seebeck coefficient, electrical resistivity and thermal conductivity — are spatially optimized within the thermoelectric material. DTP materials are tuned to achieve optimal cooling, heating and temperature control characteristics.

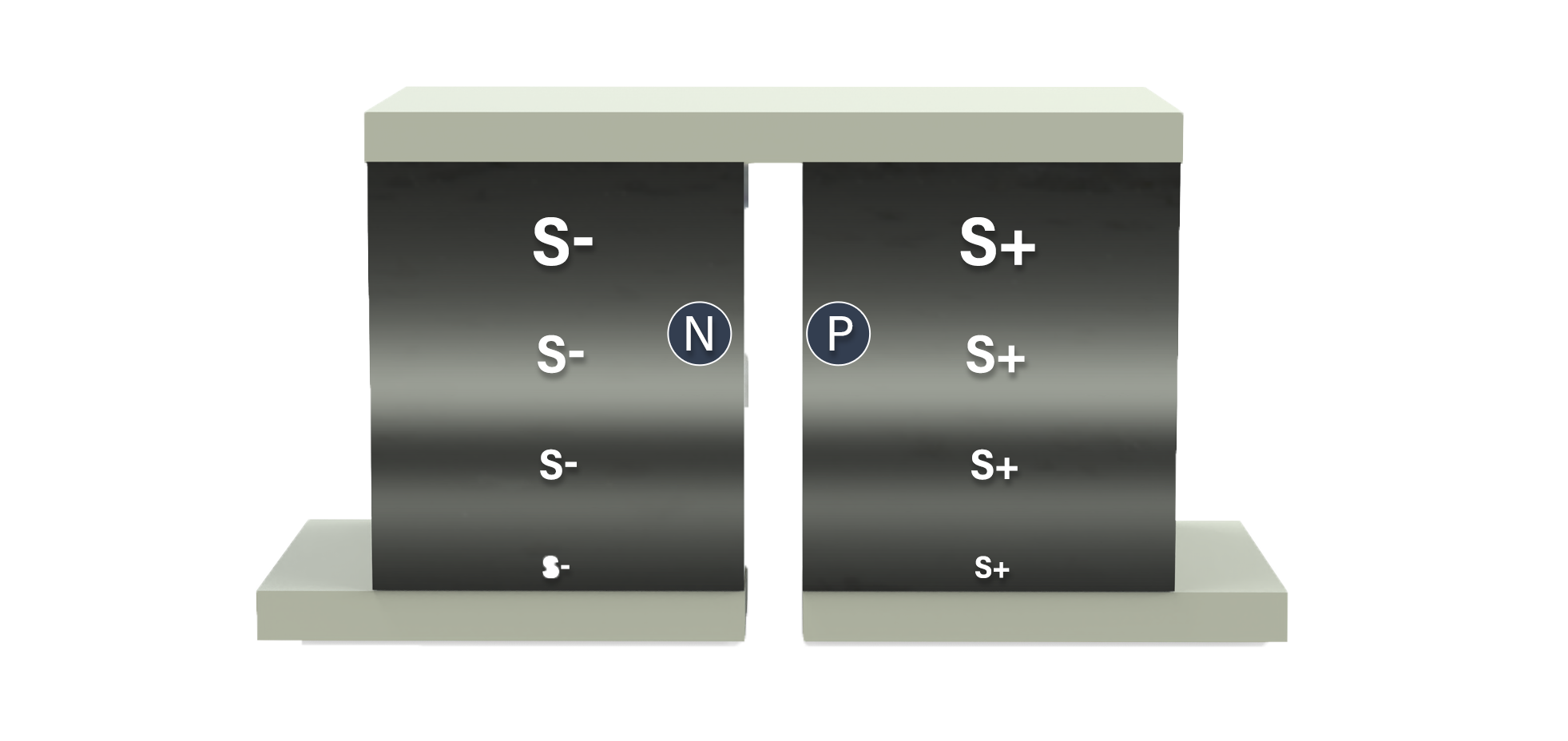

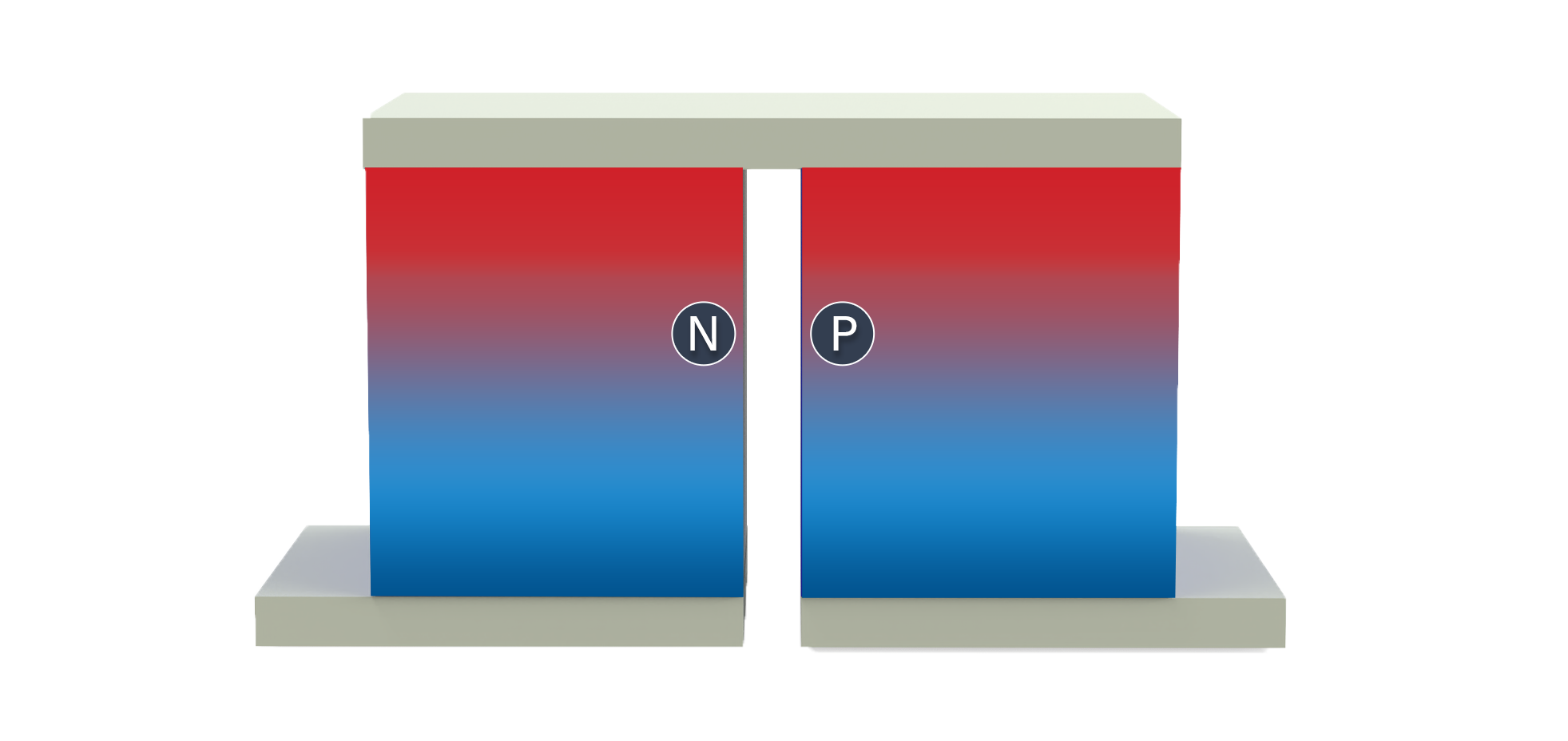

Material Structure

This figure illustrates Seebeck coefficient (S) varying with position in a thermoelectric (TE) cooling couple consisting of N and P type elements. Toward the hot end, the spatially varying Seebeck coefficient in the N type TE material is progressively more negative, while the coefficient in the P type material is progressively more positive.

Thermal Characteristics

By varying the Seebeck coefficient, electrical resistivity and thermal conductivity throughout the length of the couple, the DTP material structure changes to closely match the shape that creates optimum performance.