Automotive

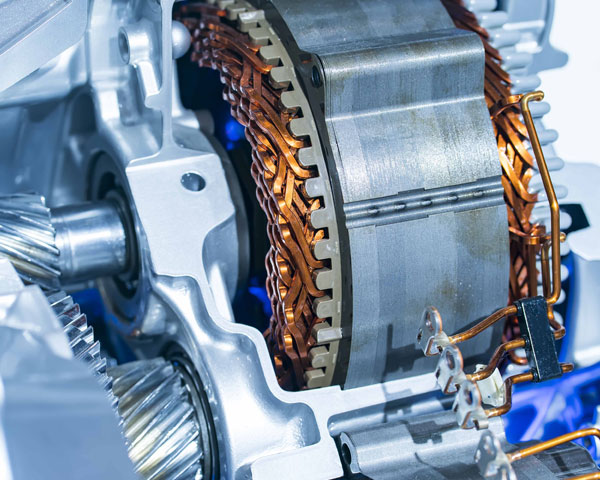

With its superior cooling capacity, wide temperature differential and high COP, our DTP technology delivers thermal management improvements to both internal combustion and electric vehicles.

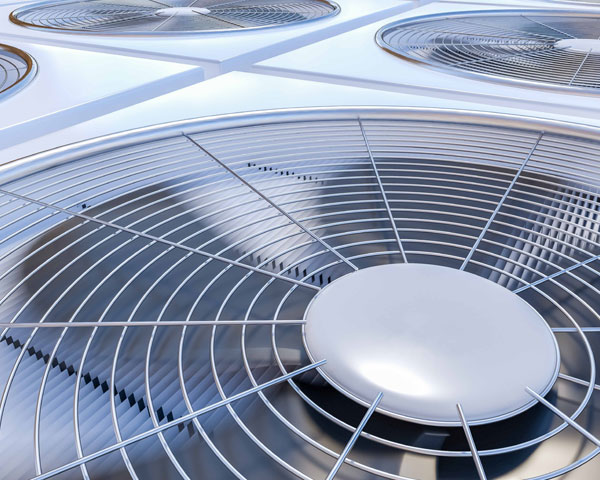

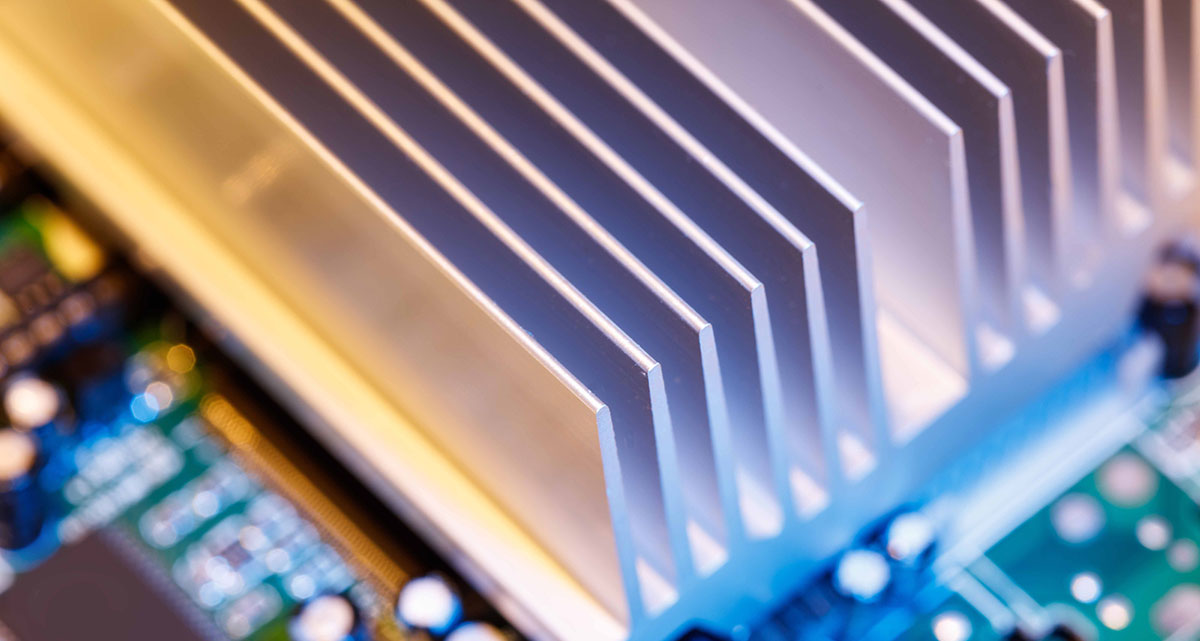

In vehicles with internal combustion engines (ICE), DTP thermoelectric devices can be incorporated as a sub-cooler into conventional vapor compression HVAC systems. The resulting hybrid HVAC systems can reach new levels of efficiency and offer more cooling capacity than similarly-sized conventional automotive HVAC systems, creating opportunities to downsize heating and cooling subsystems without sacrificing passenger comfort.

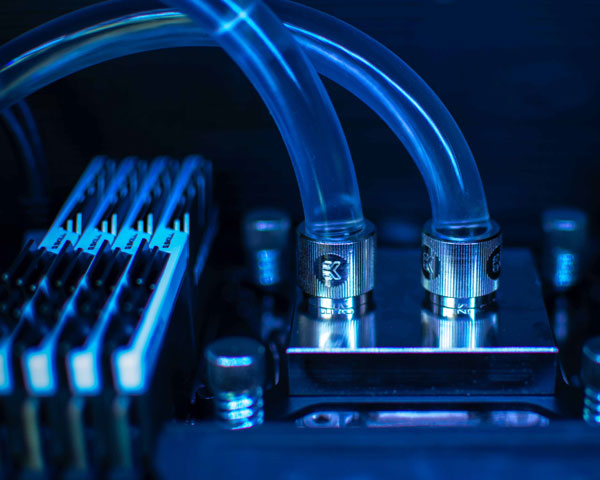

In electric vehicles (EV), a DTP thermoelectric system can provide a holistic solution to all the vehicle's thermal management needs—from efficient cooling and heating of passenger cabins to next-generation battery thermal management solutions that improve the range and longevity of automotive batteries.

Applications

- Vehicle cabin cooling and heating in both ICE and EV

- EV battery thermal management

- Exhaust heat recovery systems in ICE vehicles

- Hydrogen fuel cell thermal management